WHAT WE DO

Providing Service and Experience Across a Broad Range of Industries

Oil and Gas

FROM PIPE DETAILING TO DESIGN-BUILD

Finnoe Design has been working in the oil and gas industry over the past 10 years. With almost 900 successfully completed projects across different segments of the detailing and fabrication industry, we have the expertise to provide what you need for your project, whether that is quality pipe detailing only or complete design and build services.

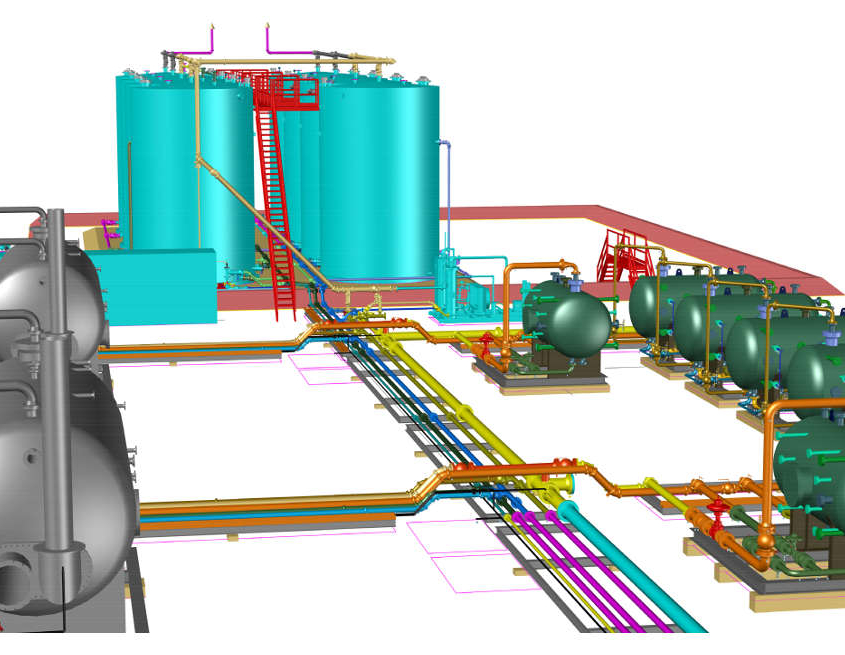

PIPE DETAILING

We have completed pipe detailing projects from Texas to Alaska’s North Slope for customers such as HillCorp and Chevron. We use AutoCAD Plant 3D to ensure complete and coordinated drawings.

DESIGN-BUILD

Provide us with your process and project specifications and we can layout and design your complete facility. Our solutions are highly functional, providing for smooth facility operation. After completion of the design process, we can take your project through the complete manufacturing phase.

3D Modeling and 3d Printed Prototyping

All pipe detailing projects are 3D modelled.

If needed, we can also print a 3D prototype of your facility to provide quick and easy visualization of the finished facility. Prototypes are especially valuable in group settings to communicate the operation of systems with mechanical components or complex functionality.

Structural

EXPERIENCE AND EXPERTISE IN THE STRUCTURAL INDUSTRY

We have been heavily involved in structural steel detailing and detail-fabrication projects since 1997. With a commitment to quality, a large detailing crew for providing shop drawings and a rapidly growing fabrication plant, we have the experience and capacity to meet your needs.

We also do miscellaneous steel, enabling trouble-free integration of structural and miscellaneous.

Detailing

Our project management experience enables us to work well with engineers, architects and contractors for a more complete and coordinated set of shop drawings. Nothing contributes more to the ultimate success of a project than quality, complete detailed drawings. Our drawings are second to none; facilitating smooth, error free fabrication and helping projects stay within budget and on schedule.

Multiple detailing squads enable us to easily handle projects up to 5000 tons.

Fabrication

Provide us with your process and project specifications and we can layout and design your complete facility. Our solutions are highly functional, providing for smooth facility operation. After completion of the design process, we can take your project through the complete manufacturing phase.

Support

All pipe detailing projects are 3D modelled.

If needed, we can also print a 3D prototype of your facility to provide quick and easy visualization of the finished facility. Prototypes are especially valuable in group settings to communicate the operation of systems with mechanical components or complex functionality.

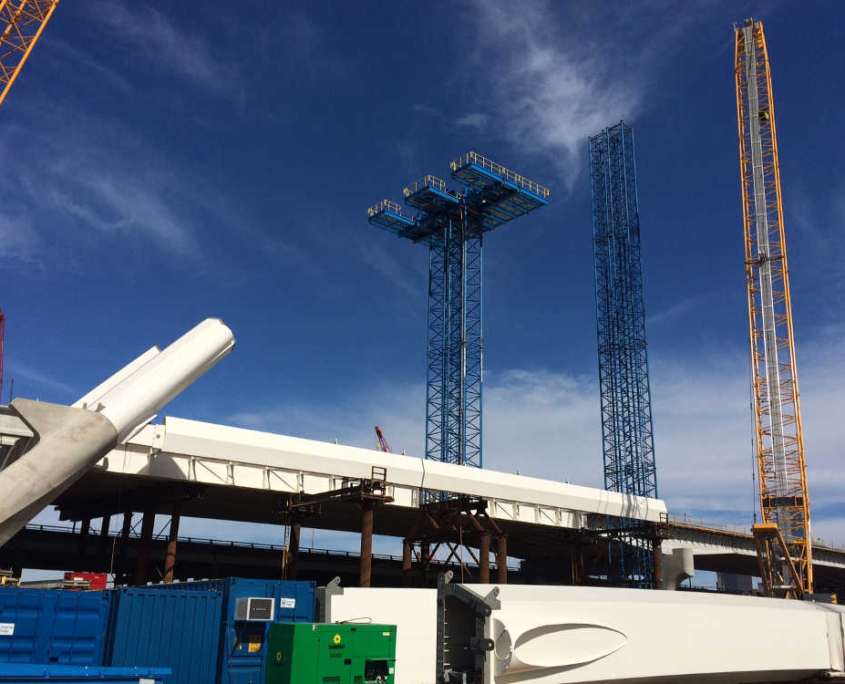

Bridges

Finnoe Design has broad experience designing and fabricating the support structures and personnel access structures required for bridge construction.

While we are sometimes approached with a complete set of design drawings, we often start with only a rough idea of what is needed. We complete the design, have it engineered, detail it, and fabricate it, usually within a very aggressive time frame. Knowing the time sensitivity of bridge projects, we make your project a top priority. Whether you are looking for temporary steel detailing only or detailing with fabrication, we will keep your project on schedule.

EXPERIENCE AND EXPERTISE IN THE STRUCTURAL INDUSTRY

We have been heavily involved in structural steel detailing and detail-fabrication projects since 1997. With a commitment to quality, a large detailing crew for providing shop drawings and a rapidly growing fabrication plant, we have the experience and capacity to meet your needs.

We also do miscellaneous steel, enabling trouble-free integration of structural and miscellaneous.

BRIDGE RETROFIT DETAILING

Finnoe Design has extensive experience detailing bridge retrofits and repairs. Our recent retrofit projects include:

Walt Whitman Bridge

George Washington Bridge

US 190 Bridge

Louisiana, Batton Rouge

Angus MacDonald Bridge in Canada

Tappan Zee in New York

Our typical process includes taking existing shop and contract drawings for the project, sometimes as old as the early 1900s, and redrawing the existing structure to ensure the new replacement pieces fit into the structure as designed. During the retrofit, we work closely with the field crews to ensure that everything is correct. We have perfected this process over the last 8 years.

Detailing

Our project management experience enables us to work well with engineers, architects and contractors for a more complete and coordinated set of shop drawings. Nothing contributes more to the ultimate success of a project than quality, complete detailed drawings. Our drawings are second to none; facilitating smooth, error free fabrication and helping projects stay within budget and on schedule.

Multiple detailing squads enable us to easily handle projects up to 5000 tons.

Fabrication

Provide us with your process and project specifications and we can layout and design your complete facility. Our solutions are highly functional, providing for smooth facility operation. After completion of the design process, we can take your project through the complete manufacturing phase.

Support

All pipe detailing projects are 3D modelled.

If needed, we can also print a 3D prototype of your facility to provide quick and easy visualization of the finished facility. Prototypes are especially valuable in group settings to communicate the operation of systems with mechanical components or complex functionality.

Miscellaneous

MISCELLANEOUS STEEL DONE RIGHT

Finnoe Design has a long successful history in the miscellaneous steel industry beginning in 1997, an experienced detailing crew, and a growing fabrication plant. Whether you need complete design-build services or detailing only, we have the expertise to integrate your miscellaneous steel seamlessly into your project.

Design

We handle all aspects of miscellaneous steel design including stair and handrail engineering. Our designs are not just functional, we strive to provide elegant solutions that work well in the space they are intended for.

Detailing

Our ability to coordinate with engineers, architects, and contractors and our extensive detailing history enable us to provide high quality shop drawings. Our drawings facilitate accurate fabrication and problem free installation.

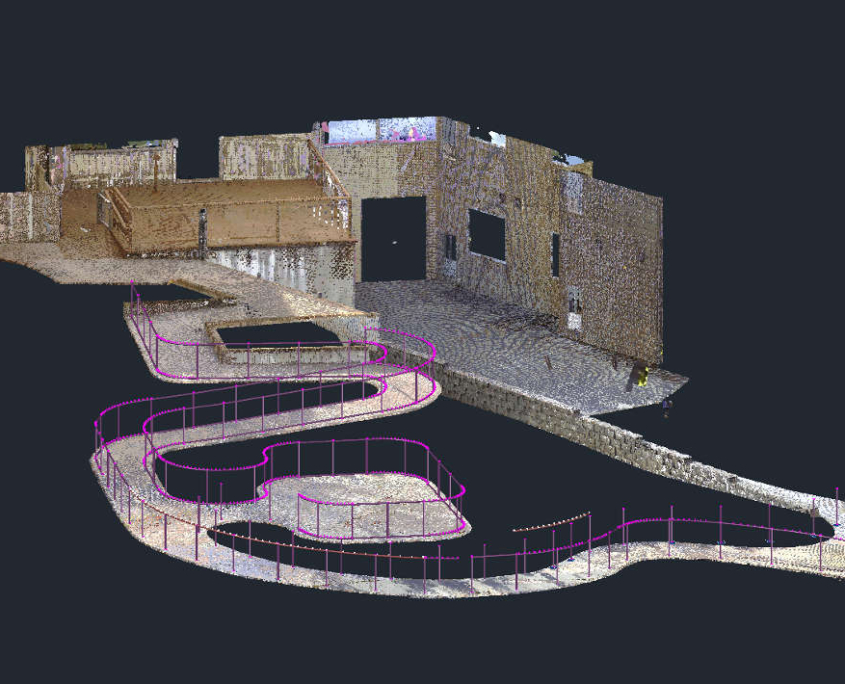

3D Laser Scanning

When integrating new steel with existing steel, we use 3D Laser Scanning technology to provide a higher quality end product. 3D Laser Scan Pointcloud Data is collected and imported into our 3D modelling software to coordinate site conditions with new steel. With this technology, fabrication is very accurate and field installation is completed quickly.

Fabrication

Our exact and complete detailed drawings lay the groundwork for precise fabrication. When we fabricate steel, it fits.

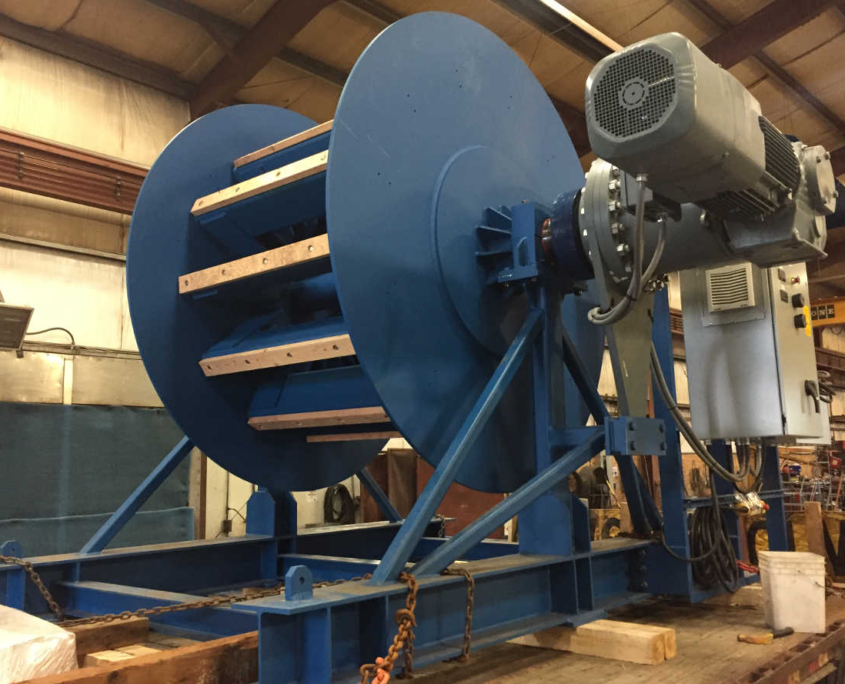

Special Construction

WE EXCEL AT SPECIAL CONSTRUCTION

From steel detailing only to design-build, Finnoe Design’s broad experience across different segments of the industry gives us the ability to execute the most challenging specialty projects.

With our trusted vendor base, in-house detailing and fabrication expertise and dedicated management, we are able to integrate the electrical, mechanical, HVAC and structural pieces of specialty projects seamlessly and efficiently.

The structure of our business allows us to be flexible and responsive to our customers’ needs and timeframes.

Our goal is to exceed our customers’ expectations every time.

Start to finish involvement allows us to provide better products that are more complete and more functional.

Design Phase

If you are starting with just a concept or have a partially completed design and need design assistance, we will work closely with you to design your project. Our diverse manufacturing background enables us to develop designs with best value and functionality to serve our customers’ needs. Detailed drawings are produced during the design phase, compressing the schedule and resulting in a higher quality product.

3D

3D models enable our customers to visualize their project before it is fabricated so modifications to the design can be made during the design phase, saving money and time. We also provide 3D printed plastic prototypes. Prototypes provide an increased level of visibility, are an excellent tool to identify needed changes to structure and function, and are especially helpful for communicating project function in a large group setting.

Manufacturing

Our quality detailed drawings provide for a smooth and rapid manufacturing phase including integration of electrical, mechanical and HVAC components.

Support

Our involvement does not stop at shipment, we stand behind our work from start to finish and will support our customers as needed, including field visits.